Humanoid Robots: Promise, Problems, and the Reality Behind the Hype

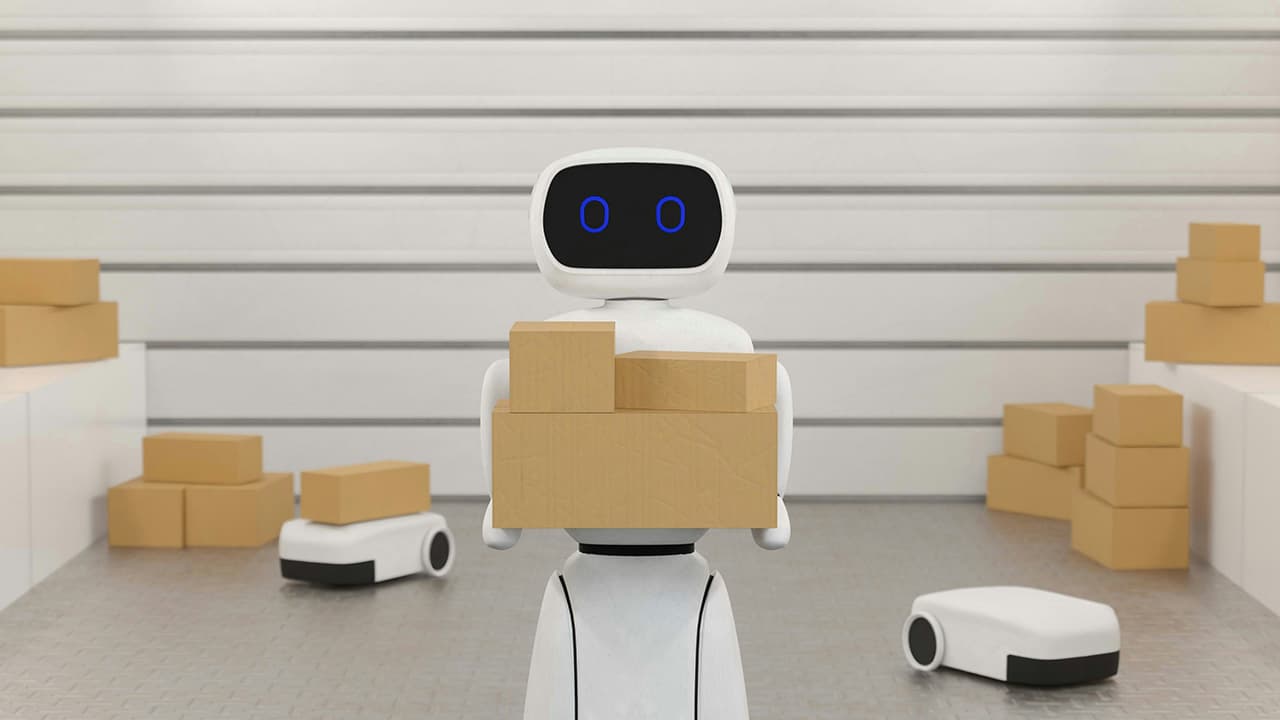

A humanoid robot is a machine designed to resemble the human body in structure and movement. Typically, it has a head, torso, two arms, and two legs, allowing it to walk upright and manipulate objects using hands or grippers. Unlike industrial robotic arms bolted to factory floors, humanoid robots are built to function in environments designed for people — homes, offices, warehouses, hospitals, and factories.

Examples include Tesla Optimus by Tesla, Atlas by Boston Dynamics, ASIMO by Honda, and Figure 01 by Figure AI. While their designs and goals differ, they share a common ambition: to build a general-purpose physical worker.

Why Companies Are Pursuing Humanoid Robots

There are several powerful economic and technological motivations behind the surge in humanoid robotics development.

First, labor shortages are growing across multiple sectors. Manufacturing, logistics, agriculture, and elder care are all facing demographic pressures and rising labor costs. A robot capable of performing repetitive or physically demanding tasks could operate continuously without fatigue.

Second, the world is already built for humans. Door handles, stairs, shelves, tools, vehicles — all are designed around the human body. Instead of redesigning infrastructure for machines, companies aim to create robots that can function within existing environments. A humanoid robot, in theory, can use the same tools and navigate the same spaces as a human worker.

Third, advances in artificial intelligence have dramatically improved machine perception and control. Computer vision systems can now recognize objects with high accuracy. Reinforcement learning enables robots to learn complex motor skills. Large language models allow machines to interpret natural language instructions. Companies like Tesla leverage expertise from autonomous driving systems to train robotic perception and planning systems.

Finally, the economic potential is enormous. A scalable, general-purpose robot workforce could represent a multi-trillion-dollar industry. Unlike single-purpose factory machines, humanoid robots promise flexibility — one machine capable of performing many tasks.

But between vision and reality lies a set of formidable technical challenges.

The Biggest Technical Challenges

1. Locomotion and Balance

Walking on two legs is deceptively difficult. Humans constantly make micro-adjustments to maintain balance. Uneven terrain, sudden pushes, and shifting loads all require dynamic stability. While robots like Atlas demonstrate impressive acrobatics, achieving reliable, energy-efficient, all-day walking remains a major engineering hurdle.

2. Dexterity and Manipulation

The human hand is extraordinarily complex, capable of delicate and powerful movements alike. Picking up a fragile object, threading a cable, or handling irregular tools requires fine motor control and sophisticated sensing. Robotic hands are improving, but achieving human-level dexterity at a reasonable cost remains unsolved.

3. Energy Efficiency

Humans can work for hours on modest caloric intake. Humanoid robots, by contrast, consume significant electrical power. Batteries limit operational time, and improving energy density without adding excessive weight is a persistent challenge.

4. Perception in Unstructured Environments

Factory floors are controlled environments. Homes and real-world workplaces are messy and unpredictable. Lighting changes, objects move, obstacles appear. Robots must reliably interpret complex visual scenes and make safe decisions in real time.

5. General Intelligence and Adaptability

Programming robots for a single repetitive task is manageable. Building a system that can flexibly perform many tasks — with minimal retraining — is far harder. True general-purpose functionality requires advanced reasoning, planning, and continual learning.

6. Cost and Scalability

For humanoid robots to become widespread, they must be affordable. High-precision actuators, sensors, and computing hardware are expensive. Manufacturing at scale while maintaining reliability is a massive industrial challenge.

Are Humanoid Robots Overhyped?

In some ways, yes.

Public demonstrations often showcase carefully choreographed tasks in controlled environments. Viral videos can create the impression that fully autonomous household robots are just around the corner. In reality, many systems still rely on teleoperation, simplified scenarios, or limited task scopes.

The timeline for widespread deployment is uncertain. Achieving reliability comparable to human workers — especially in complex environments — will likely take longer than optimistic projections suggest.

However, dismissing humanoid robotics as pure hype would be equally misguided.

Unlike past robotics waves, today’s efforts are supported by unprecedented advances in AI, computing power, battery technology, and simulation tools. Machine learning enables robots to train in virtual environments before deployment. Vision systems now rival human-level recognition in some domains. Cloud computing allows large-scale model training.

Moreover, even partial success could transform industries. A robot that can reliably perform warehouse sorting, simple assembly tasks, or routine inspection work would still represent significant economic value.

The Realistic Outlook

Humanoid robots are unlikely to immediately replace broad segments of the workforce. Instead, their adoption will probably begin in structured environments such as warehouses and factories, where tasks are repetitive but benefit from flexibility.

Over time, improvements in dexterity, energy efficiency, and AI reasoning could expand their capabilities. As costs fall and reliability rises, new applications may emerge — from elder assistance to hazardous industrial work.

The concept of a general-purpose physical worker remains one of the most ambitious goals in engineering. The path forward will require breakthroughs not only in artificial intelligence, but also in materials science, mechanical engineering, battery technology, and large-scale manufacturing.

In short, humanoid robots are neither science fiction fantasy nor immediate reality. They represent a high-risk, high-reward frontier — one where the technical challenges are immense, the hype is sometimes inflated, but the long-term potential is undeniably transformative.